Simply put, Gupta Permold is a world-leader in the permanent mold aluminum casting industry. From pouring to trimming to heat-treat, our state-of-the-art equipment and technology puts us at a distinct competitive advantage relative to our competitors in the commercial casting market.

We commonly employ such advanced techniques as:

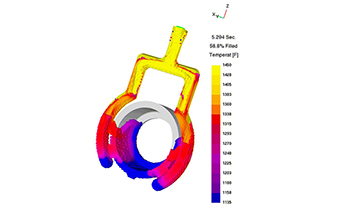

- Solidification modeling

- Flow Simulation

- Virtual casting Optimization

- Infra-red thermal management

- Non-contact mold cleaning

- Automated & Computerized tilt-pour

- Programmable melt system

- Sub-gating Technology

Just to name a few. Pushing the envelope and exceeding expectations is what we do, so we invite you to look at us further and consider us on your next aluminum project.

[download

brochure]

permanent mold aluminum castings

"A

Better Way to Cast Aluminum" & "An Example of Mold

Tolerances" as

featured in Machine Design Magazine. Written by Arun K. Gupta,

Gupta Permold Corp.

"Permanent

Mold Castings: Pathway to Quality" from Technology Tips reprinted from MetlFax Magazine. A great

article surveying the pros and cons of the popular casting

methods with a special emphasis on Permanent Mold.

Samples,

Samples, Samples...

Take

a look at some sample castings we've made for a wide variety

of applications. Chances are what you are trying to do, we've

already done before!

Permold

Process at a Glance

The ancient history and simplicity of our process enables

potential customers in other processes to make the leap feeling

very secure. Come learn how our process works so you to can

Gain the Advantage.

9

Advantages of of Permold

OK, so we couldn't think of 10. But 9 isn't that bad. Come

learn why our customers keep coming back to us.

Comparison

Study: Permold vs. Pressure-Die Casting and Sand Casting

Find out how our process compares to sand casting and pressure-die

casting in terms of finance, logistics, and engineering specification..

A

Unique Feature: Molded Inserts

Something

the other guys can't do. Come learn how molded inserts can

get you away from heli-coiling, drilling/tapping, and heavy

metals like ductile iron and steel.

Designing

for Permold

Designing for our process is very intuitive. Look over our

quick design guide for a flavor of what our process can achieve.

machining

It's

simply not enough to supply the world with high-quality castings.

Often parts need drilled, tapped, faced, milled, lathework,

etc. If Gupta Permold can't get your casting to net shape,

allow us to furnish your parts complete with our full scale

manual and CNC machining capability.

heat treating

A variety

of metal tempering processes to meet and exceed your hardness

and strength requirements are provided in-house to greatly

reduce your lead-times.

welding

For general

fabricated weldments, we operate highly-skilled welding shop.

Our certified welders can perform MIG, TIG, ARC, brazing,

and other metal-joining processes to suit your needs.

metal finishing center

Our as-cast

surface finish not good enough for you? Pick from our laundry

list of highly popular metal finishes, or make one up yourself.

Our in-house finishing center can meet and exceed all of your

aesthetic requirements.